Email Us

sales@boltking.co.uk

Call Us

01952 350100

01952 350200

We have a comprehensive range of automated and manual machinery at our site in Telford. Our plant is suited to manufacturing special fasteners in typical batch quantities of 50 - 5000 pieces. We welcome you to visit our facility at any time for expediting purposes.

Hot forging has a number of advantages over machined product, particularly headed fasteners, such as Special Hexagon Bolts and Socket Head Capscrews. Unlike many of our competitors, Bolt King manufacture and heat treat all of our hot forging dies in-house, allowing for industry-leading turn-around on hot forged special bolts.

Key benefits of hot forging:

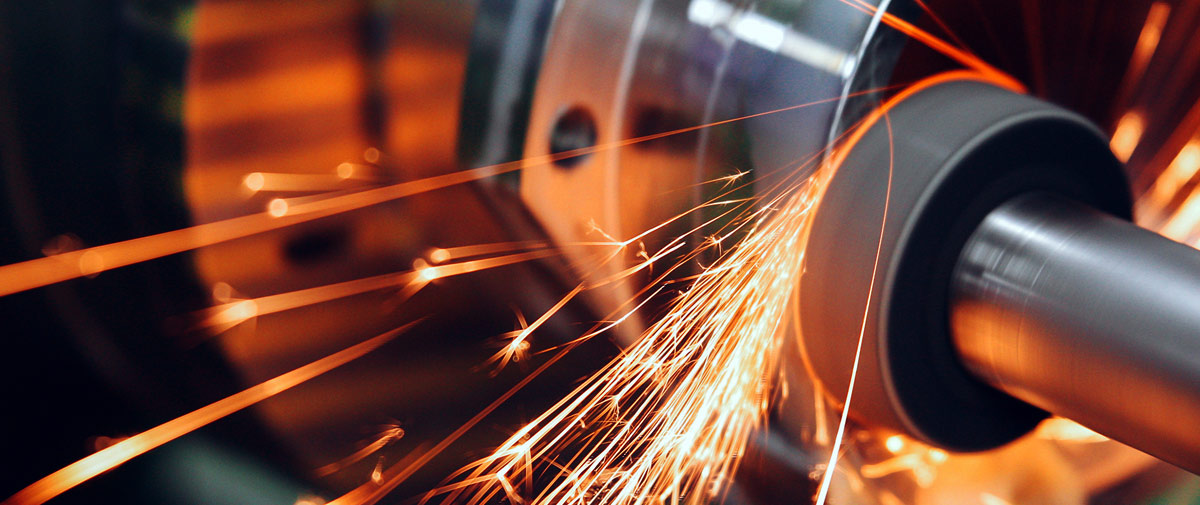

We have 8 CNC Lathes, 6 Semi-Auto EMI-MEC Lathes, and 8 Manual Capstan Lathes for precision turning. For Milling, we have 6 CNC Vertical Machine Centres with 4th Axis.

Precision machined fasteners, while sometimes more labour intensive, often represent the fastest order-to-manufacture production route for time critical deliveries - Our Project Managers can have our Production Engineers cutting metal within hours of contract reviewing your order.

25 Ton Thread Rolling Machine, Centreless Grinding, Spark Eroding EDM, Straightening Press, Automated Bandsaw, Screwing Machine, Heat Treatment Furnace, Application Plant for for PTFE and Organic Zinc Coating.

Special Fasteners In Exotic Alloys, Including

Inconel & Super Duplex

Bolt King Ltd 2025 | All Rights Reserved | Privacy Policy | Built by